FLARE OPERATION AT BOTANY

WHAT ARE FLARES?

Flares are a key safety and environment management tool used in refineries and petrochemical facilities. They will safely burn flammable waste gases which cannot be recovered or recycled in the processing plants and therefore avoid the release of emissions and odours. Flares are also used to safely burn process gas when a plant is shutdown, this ensures that the integrity of the plant and the safety of the community is ensured.

The flares are generally of three types

1. Elevated flares - where the flare tip is elevated above the ground.

2. Ground flares - where the flare tip is at ground level, which is fenced off with heat shields to keep people at a safe distance from the heat produced when the flare is operating.

3. Enclosed ground flares – where the flare tip is in an enclosure at ground level which prevents noise and light from impacting off site.

The use of flares is minimised to the extent that is possible. This is to reduce any impacts the flaring has on the community and to maximise the efficiency of operations. Examples of when the flares need to be used include:

· Taking the process plants off line for maintenance

· Starting the process plants up following maintenance

· When safety shutdowns activate

· Purging of gases during plant operations

· Utility interruptions such as power failures.

WHERE ARE THE FLARES ON THE BIP?

Qenos has four flares in operation in the north-western corner of the Botany Industrial Park (near the intersection of Anderson and Baker Streets, Banksmeadow). These are:

· Two enclosed ground flares (approximately 12m high) for the Olefines Plant.

· One elevated flare (approximately 70m high) for the Olefines Plant.

· One combined elevated/ground flare (approximately 20m high) for the Alkatuff Plant.

The community is generally familiar with the operation of the elevated flares and is able to recognise when they are being used.

HOW DO THE FLARES WORK?

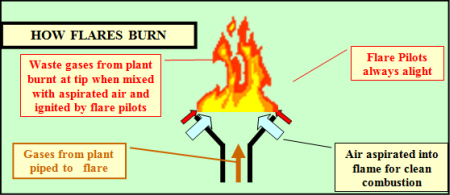

Each flare has pilot lights to safely ignite waste gases when they are sent to the flare. The gas needs air to burn correctly and this is either aspirated by the gas flow to the flare (like a barbeque burner) or with steam aspirators to provide adequate air. The mixture of air and gas ignited by the pilots is safely burnt.

Inadequate air flow will cause the flare to be smoky. There maybe some smoking when the flares initially light until enough air is added by the control system. The control systems operators use cameras to monitor the flame and adjust the amount of air to ensure that it is not smoking. For significant plant shutdowns such as those caused by power failures the flares may smoke for several minutes.

The noise from the flares increases as the rate of flaring increases. This is caused by the extra steam to the flare and the combustion of a larger amount of gas. The flare impact is generally only noticed in the community during larger flaring when the shutdown systems are activated such as those caused by power failures.

WHAT IMPACT DO THE FLARES HAVE?

The flares can have the following impacts off site:

1. Light/Flames

2. Smoke

3. Noise

4. Emissions/odours.

Members of the community may sometimes become concerned when large flares are visible and may mistake them for a fire or emergency at the plant. This happened on the 26th of May, 2012 when the Olefines elevated flare activated to safely combust process gas following a plant shutdown.

The elevated flare is very noticeable and from some locations it may appear that there is a large uncontrolled fire, this is not the case and the gas is always burned in a controlled and safe manner The attached photo is of the Olefines elevated flare in operation.

The enclosed ground flares have a series of small burners in an enclosure at ground level. When waste gas is sent to the ground flare the initial ignition of all the small burners makes a rumbling sound similar to a loud roll of thunder. The flames from the ground flare are sometimes visible to the community and have been mistakenly identified as a fire on the plant.

HOW IS QENOS MINIMISING THE FLARE IMPACT?

Qenos uses the flare as little as possible as any gas that is flared is a loss of valuable feedstock and reduces the overall efficiency of our production. Regrettably at times the frequency and volume of flaring is higher than Qenos and the community would like.

The Qenos use of the flare is managed in the following ways to minimise community impact when it is in operation:

1. Carry out the flaring in daylight hours as much as possible to minimise ‘out of hours’ impact.

2. Limiting the size of flares for planned flaring.

3. Rapid reduction of plant processing rates for significant interruptions to operations such as power failures.

4. Regular performance monitoring and reviews of flare operation to improve the flares’ operation and identify ways of reducing the level of flaring.

5. Public reporting of complaints via our community consultation processes.